What is BoxJoint™?

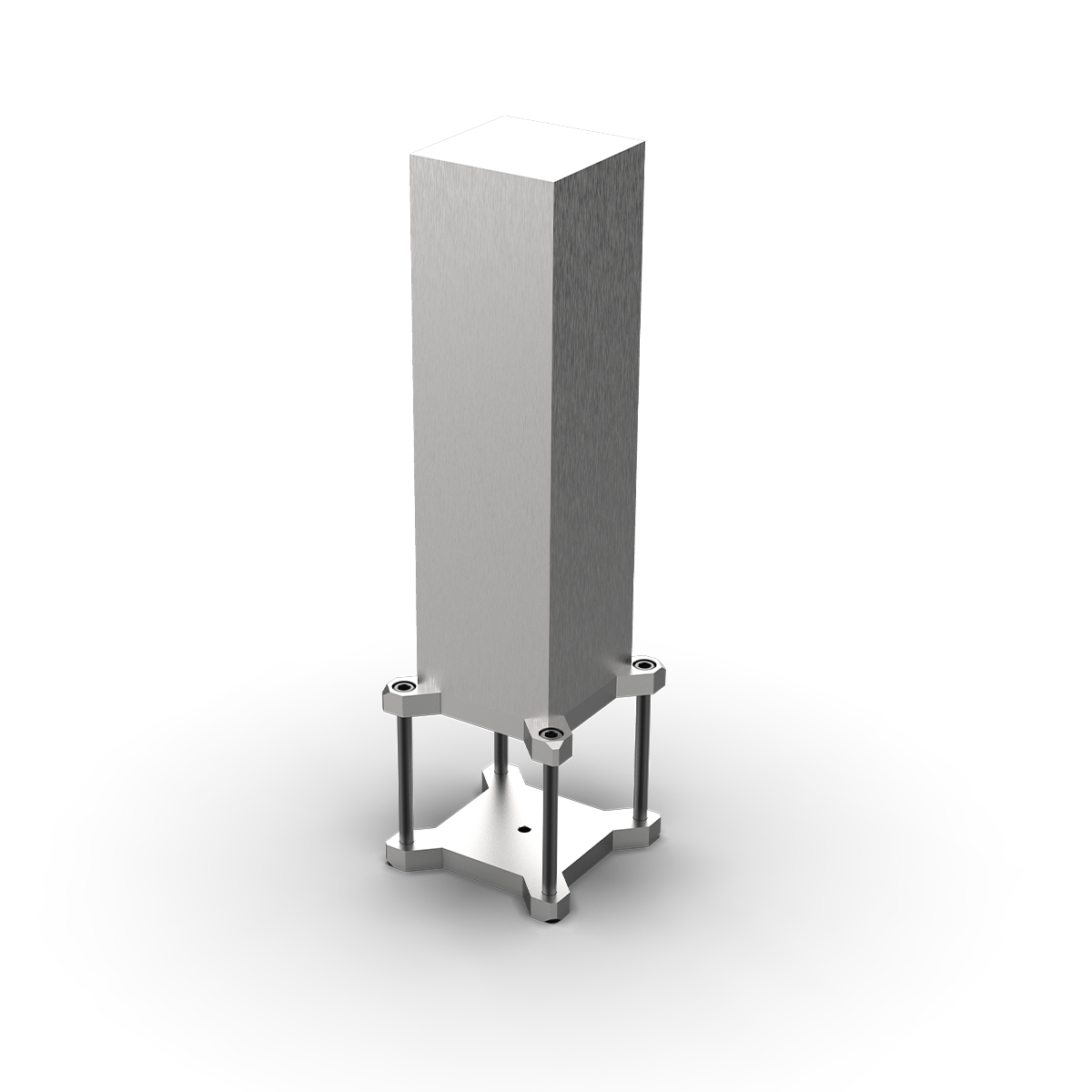

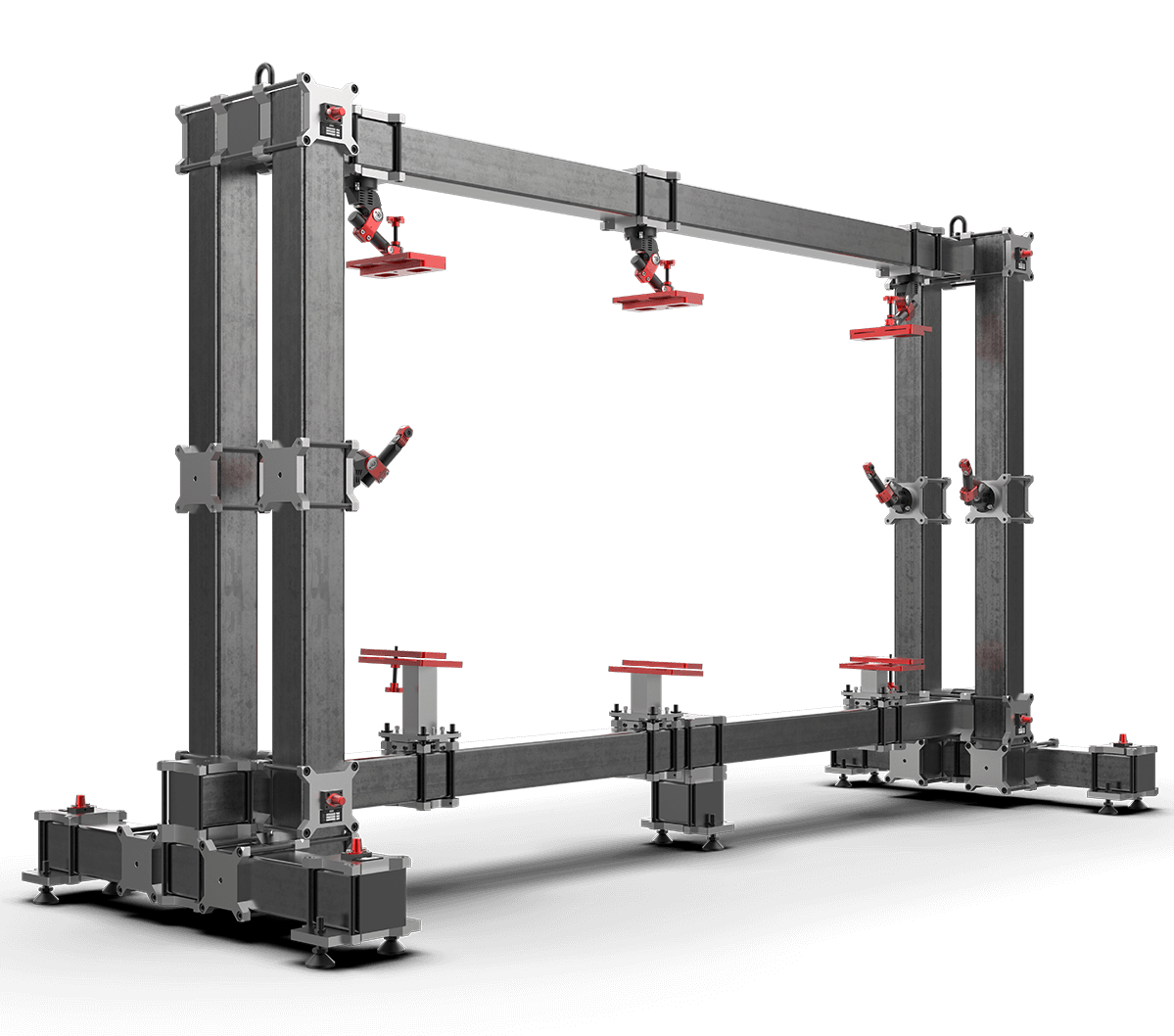

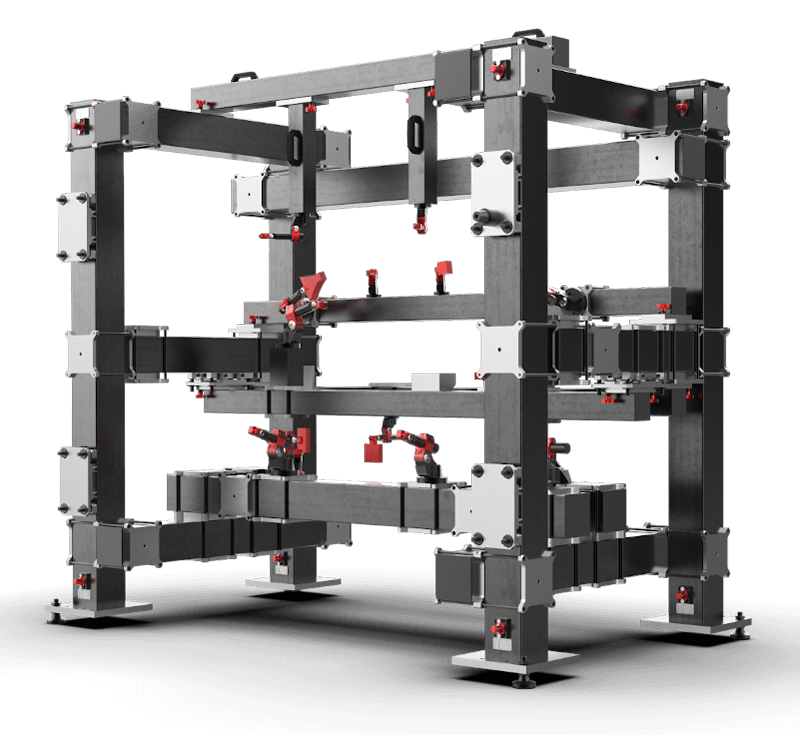

The BoxJoint™ system is an arrangement of tubes and joints, which together form a framework. There are no welds between the connecting pieces in the system, instead the parts are fixed together using the force of friction. Dowel Pins can be used to mechanically lock the system.

HBOX™ units are used to join standard tubes to form the framework of the jig. The framework is set to a loose tolerance facilitating a quick assembly process and the use of standard low cost beams. The final accurate interface between the jig and the component is achieved through adjustable HFLAG™ and HSHIMBOX™ units.

Key Components

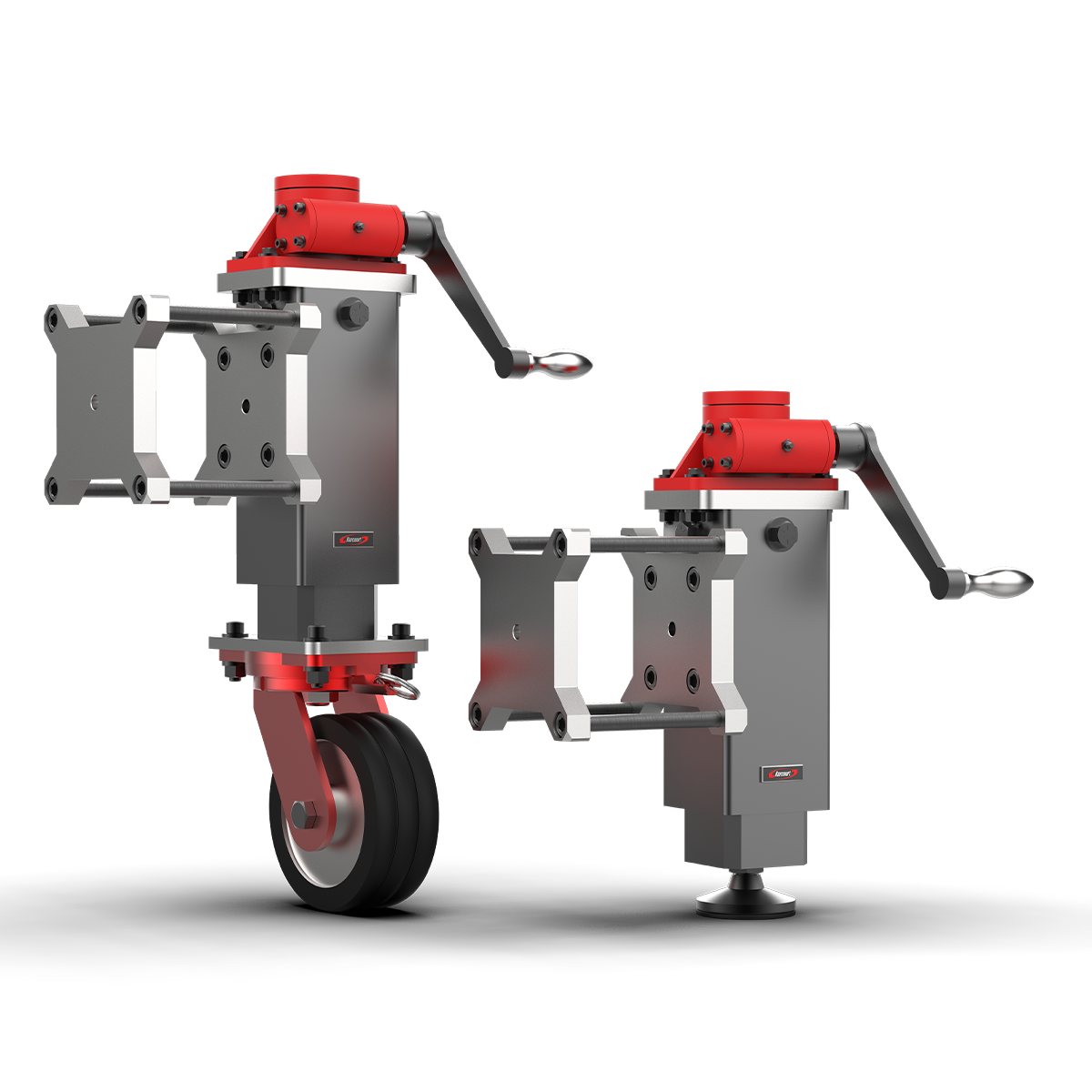

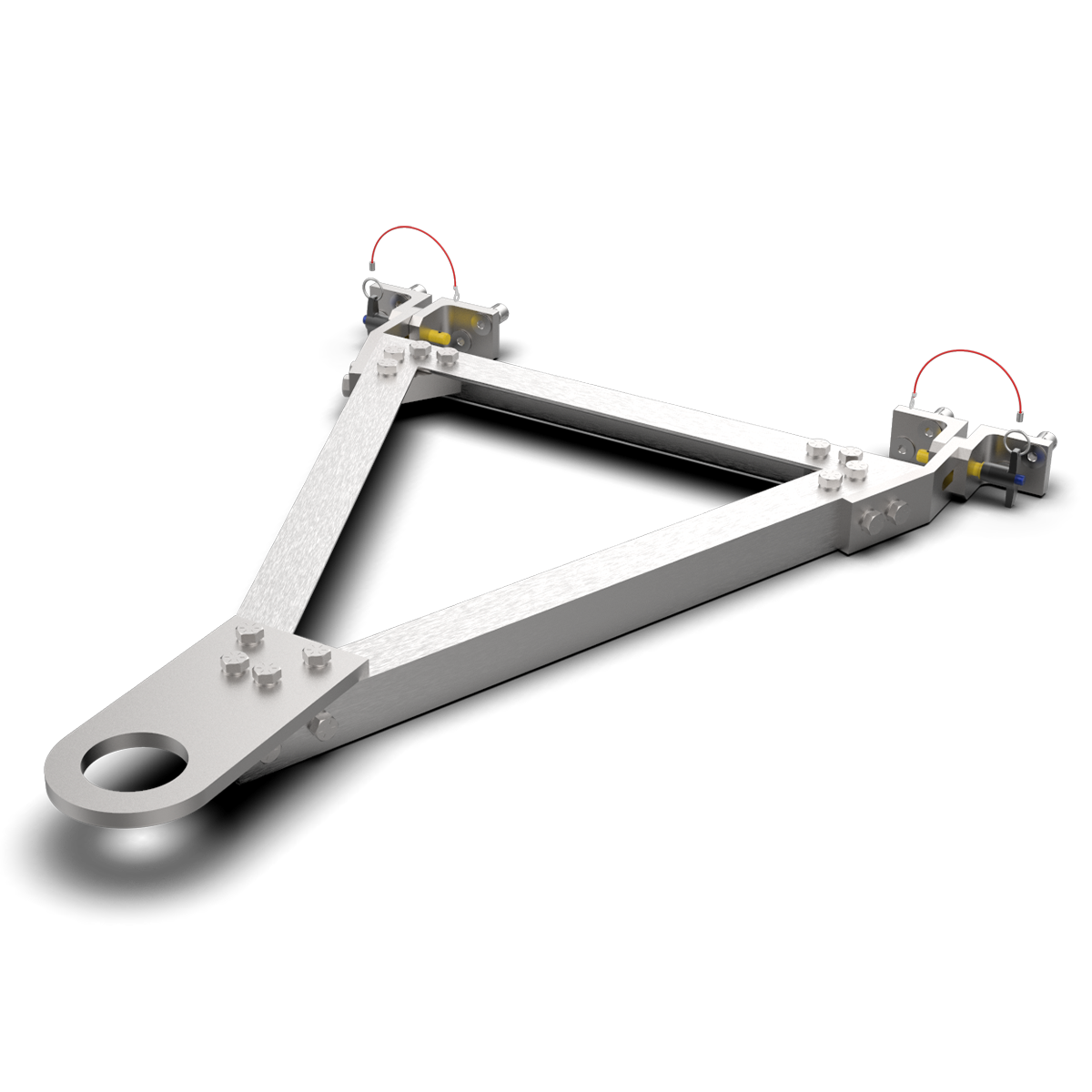

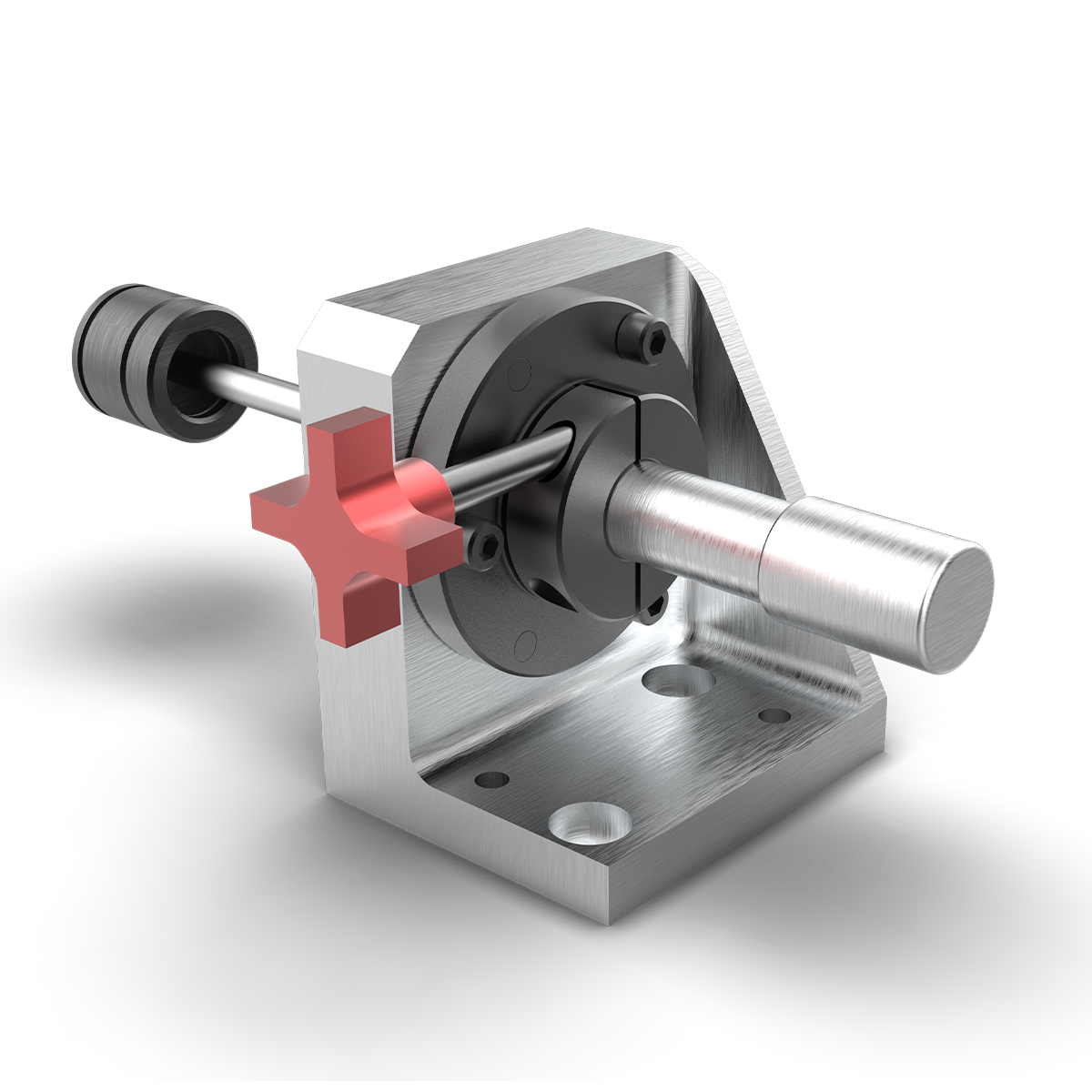

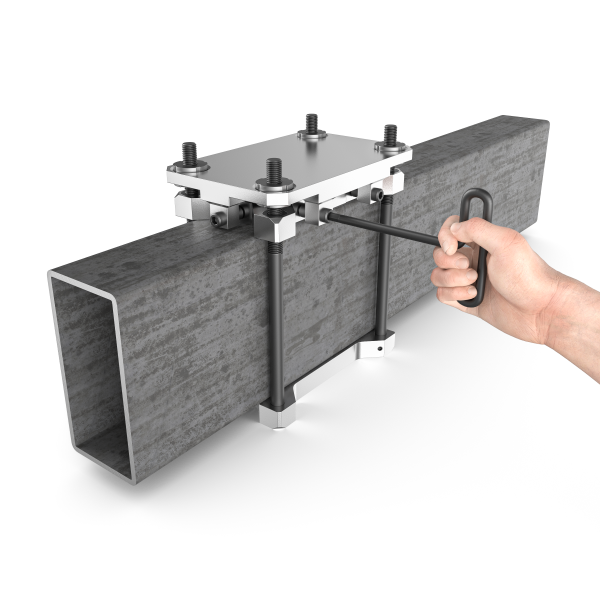

HBOX™

HBOX™ creates a structure fast by utilizing off-the-shelf aluminum, steel, or carbon fiber beams joined with plates and bolts. Bolts are pulled to a high torque to give a rigid friction joint, equal in stiffness to a weld. HBOX™ eliminates welding and stress reliving on jig frames.

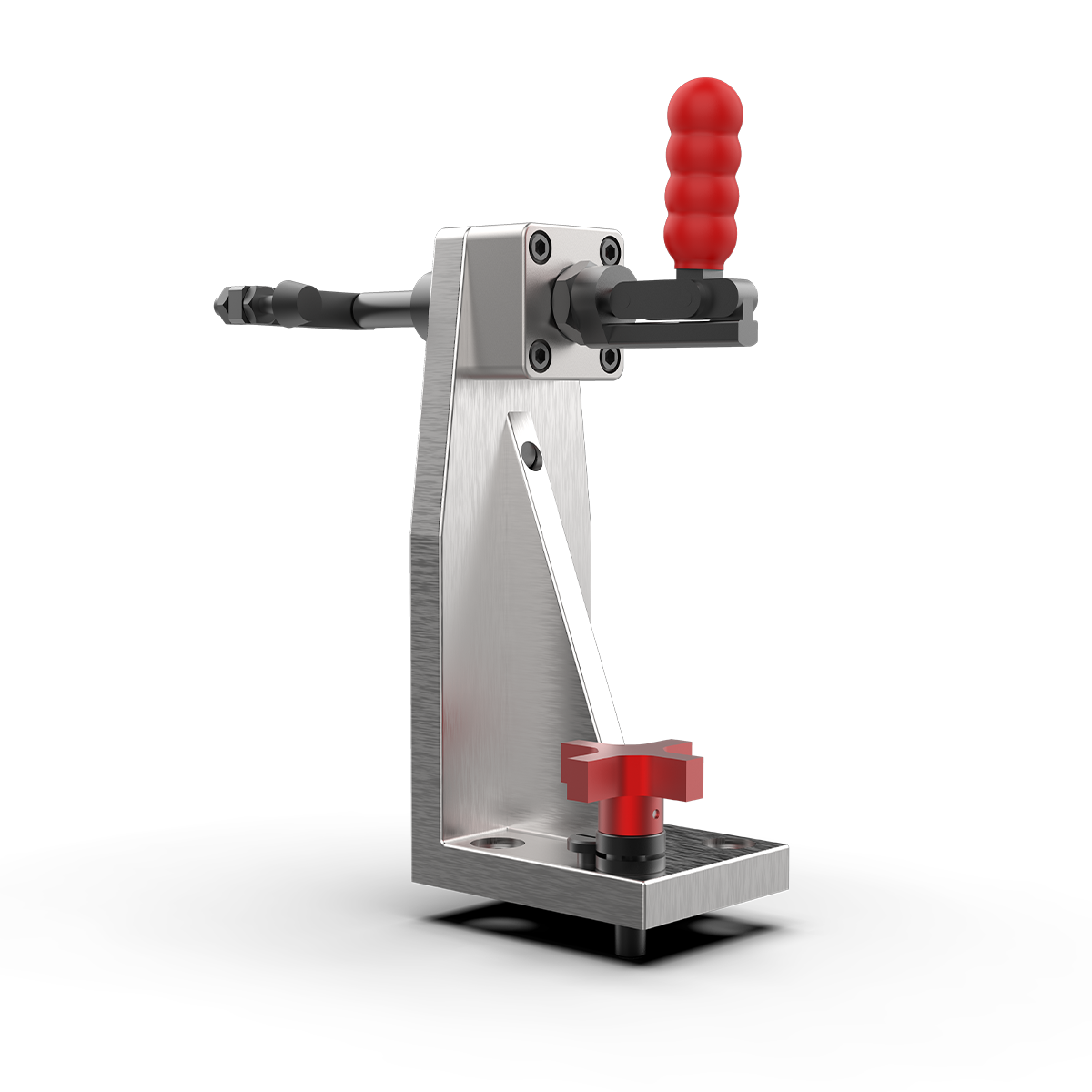

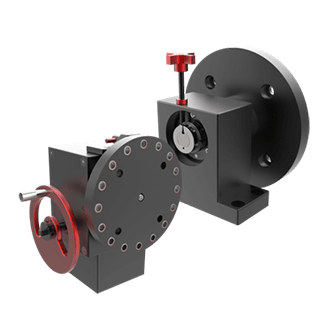

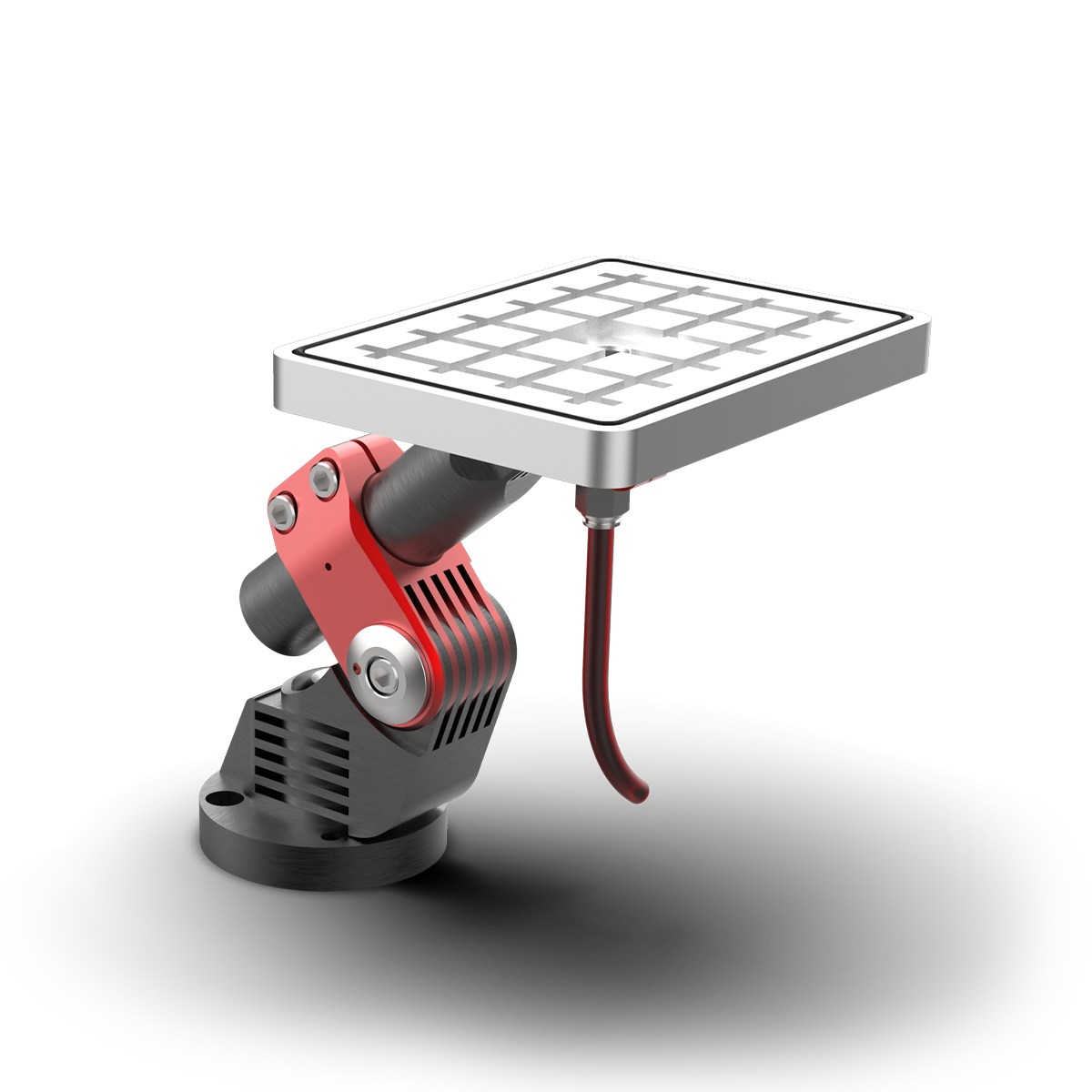

HFLAG™

HFLAG™ is a 6 DOF (degrees of freedom) index that is manually adjusted then locked when the desired location is reached. Standard end-effectors are available for clamps, rest pads, round (4 way), and slotted (2 way) bushings. HFLAG™ eliminates expensive, custom-made risers, locators, shims, etc.

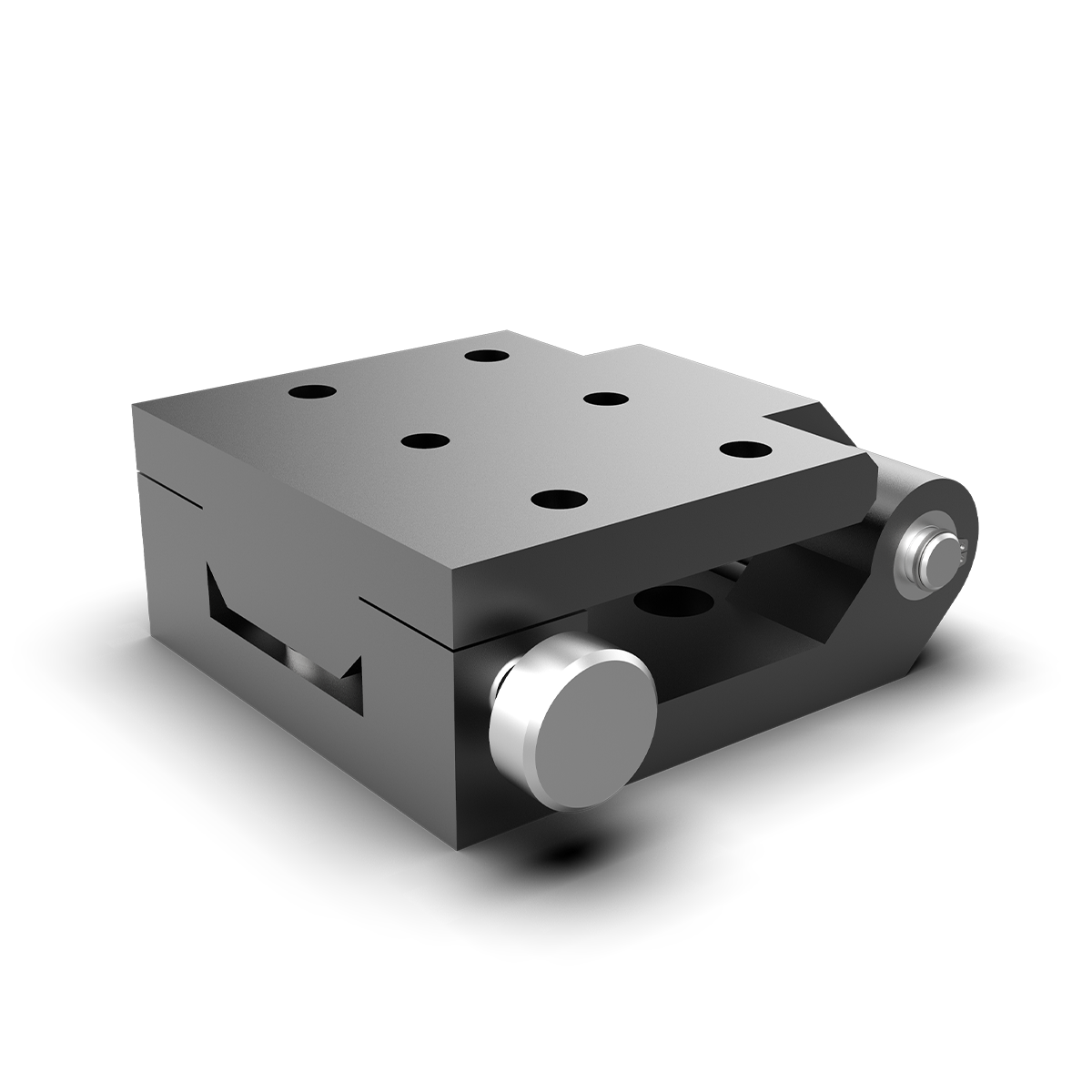

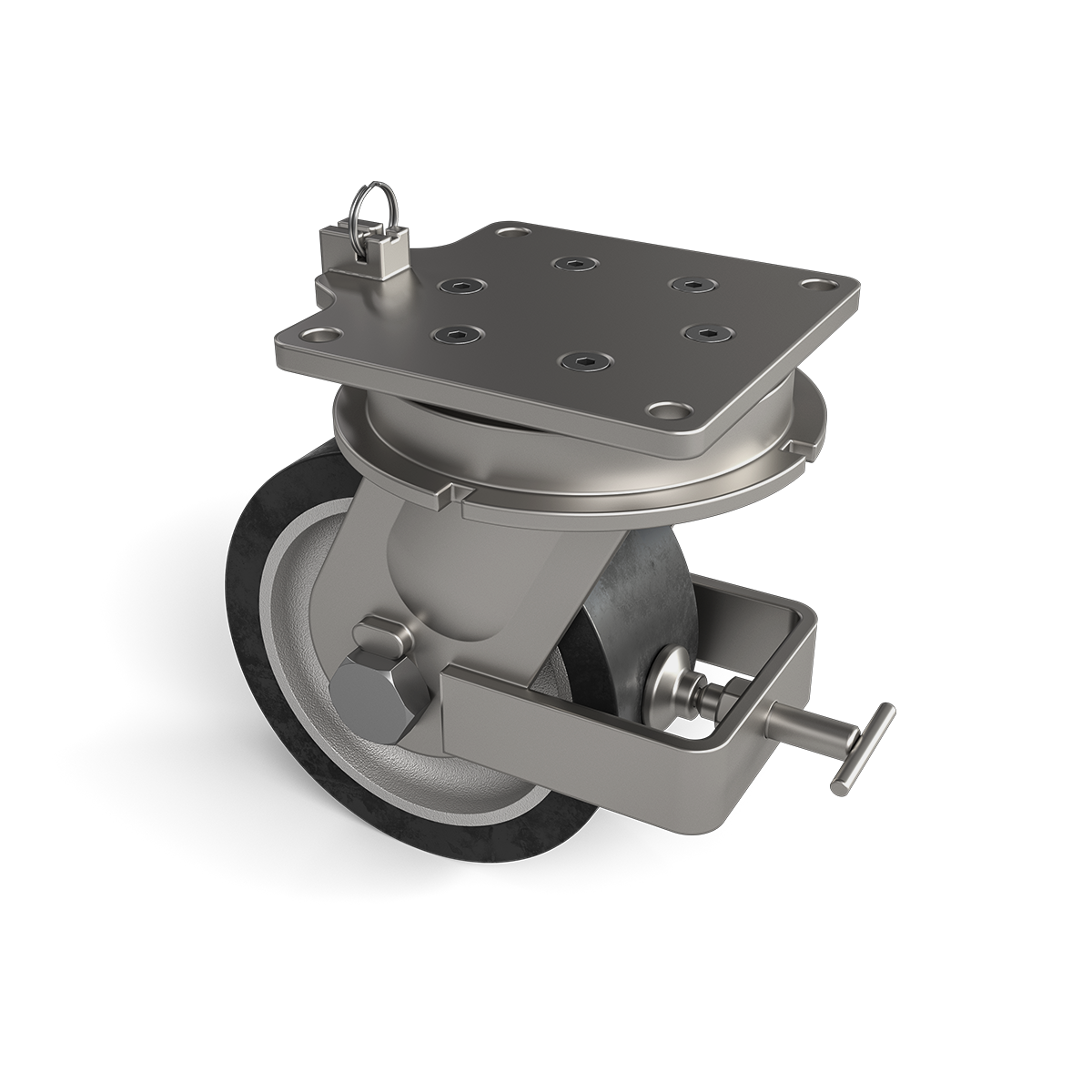

HSHIMBOX™

HSHIMBOX™ technology enables users to integrate drill jigs, header-boards and other high tolerance, fixed tooling into a BoxJoint™ environment. The top plate of the unit is modified with a mounting pattern for attachment. An operator can set a HSHIMBOX™ into a tight-tolerance position within a few minutes.

Revolutionizing Manufacturing

Repeatability

Proven in the most demanding production environments in the world.

Material Options

Design to work interchangeably with standard, off-the-shelf tubes in either steel, aluminum, or carbon fiber.

"Lego" Concept

All BoxJoint™ elements can be reconfigured to absorb design changes or create endless tools. No more tooling boneyards, no more tooling storage costs.

Compatibility

Easily integrate electrical, mechanical, pneumatic systems such as LED lighting, air lines, controls, etc.

Light on your Budget

Faster to design, faster to build, easy to modify, reconfigurable - all translate to costs savings. One third party study proved 80% cost savings when compared to traditional tooling.

Short Lead Times

In stock, easy to assemble and calibrate.

Sweet Spot Analysis

Online Ergo Products

Configurability

–

Cost

Stress Analysis

–

Safety Features

Precision

–

High Production

Lead Time

Quality

Origin

BoxJoint Tooling

Configurability

Cost

Stress Analysis

Safety Features

Precision

High Production

Lead Time

Quality

Origin

Factory Automation

Configurability

Cost

Stress Analysis

Safety Features

Precision

High Production

Lead Time

Quality

Origin

What Our Customers Say

Approved BoxJoint Integrators

Expert end-to-end support

Aciturri Aeronáutica

Headquartered in Spain, Delivering throughout Europe.

Ascent Aerospace

Headquartered in Michigan, Delivering throughout North America.

BAZ Aircraft

Headquartered in Israel, Delivering throughout the Middle East.

Want to become an Approved BoxJoint Integrator?

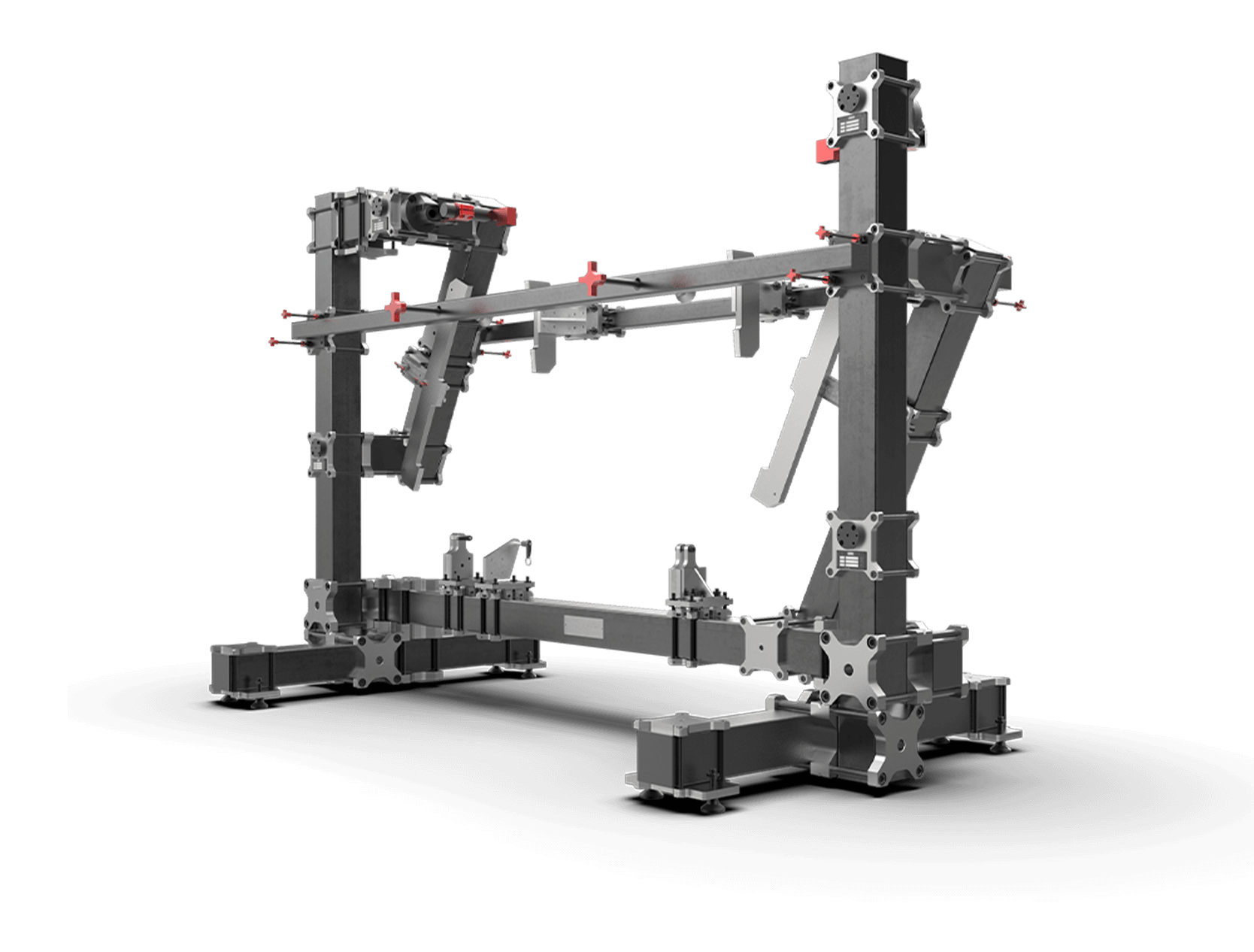

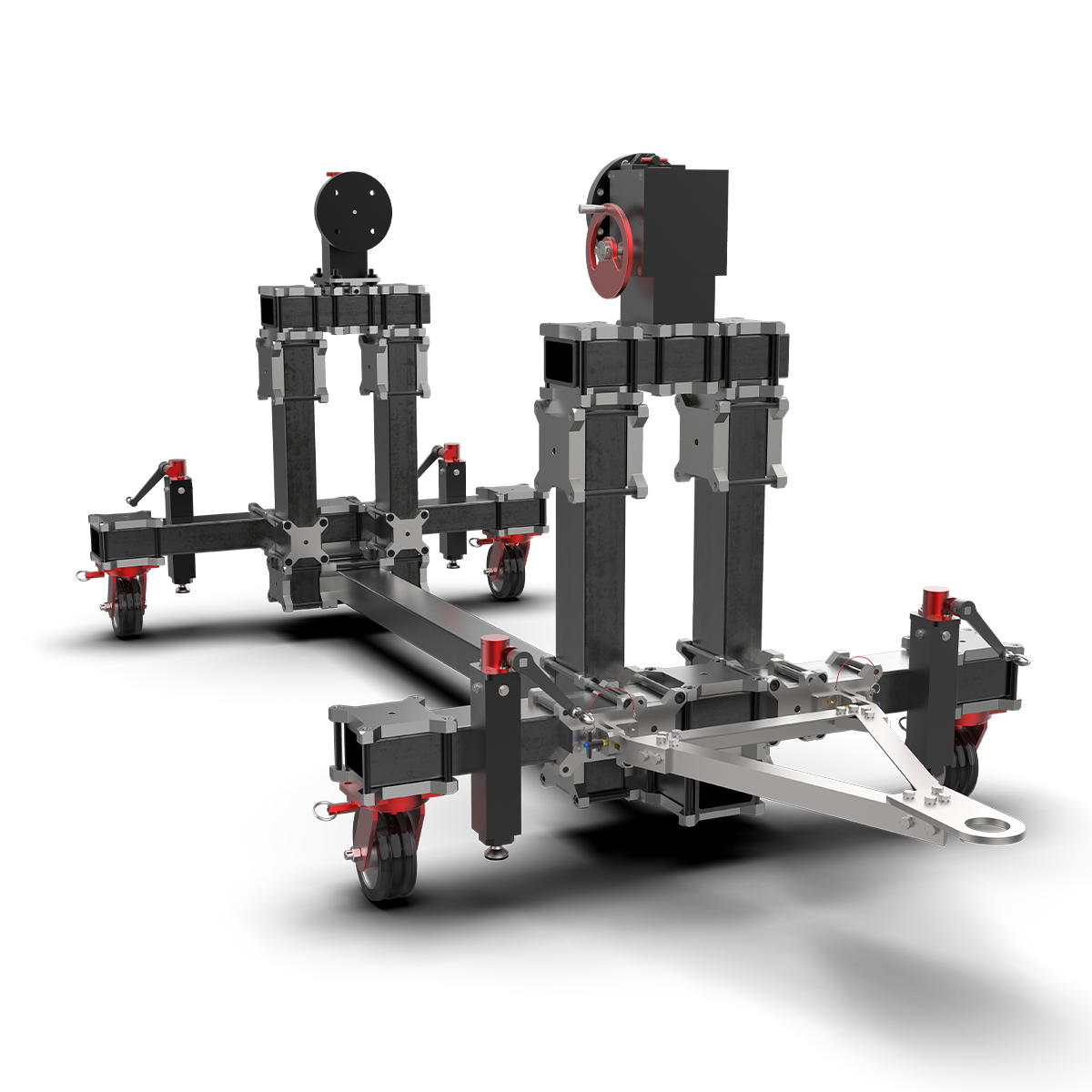

Applications

From the Aerospace to Automotive industries, BoxJoint™ versatility is limitless. We have worked with hundreds of companies small and large, providing them with customized and engineered tooling solutions for their programs. The modularity of BoxJoint™ makes it perfect for one-off applications to full assembly lines.

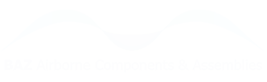

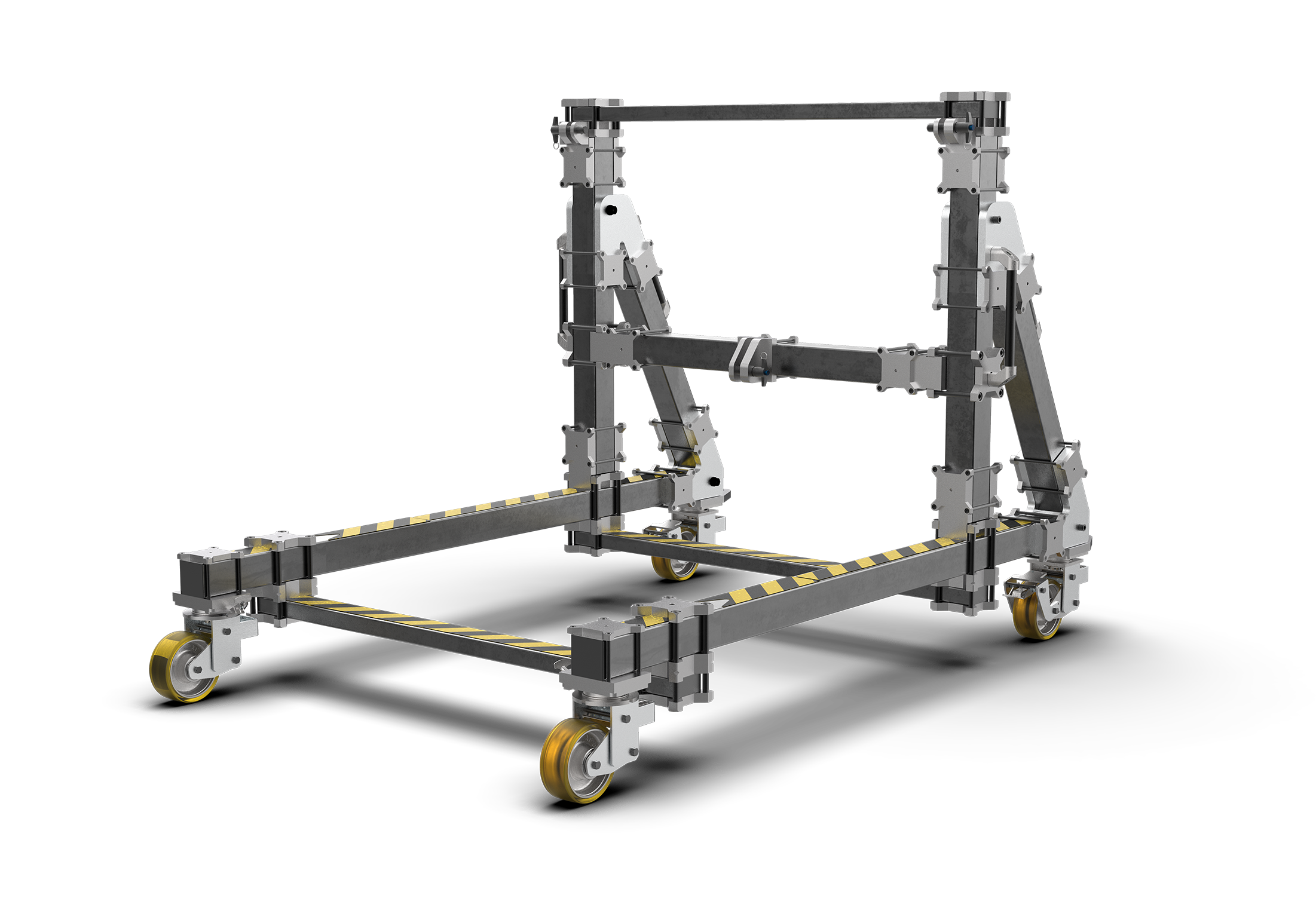

Autoclave Tooling Cart

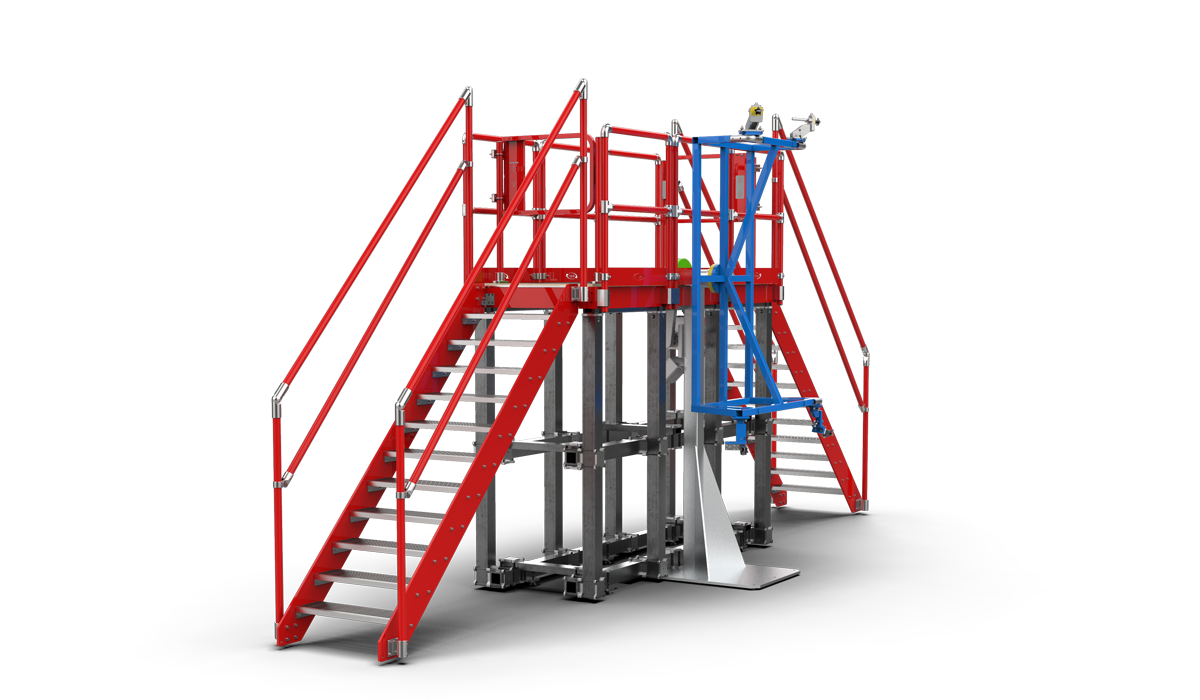

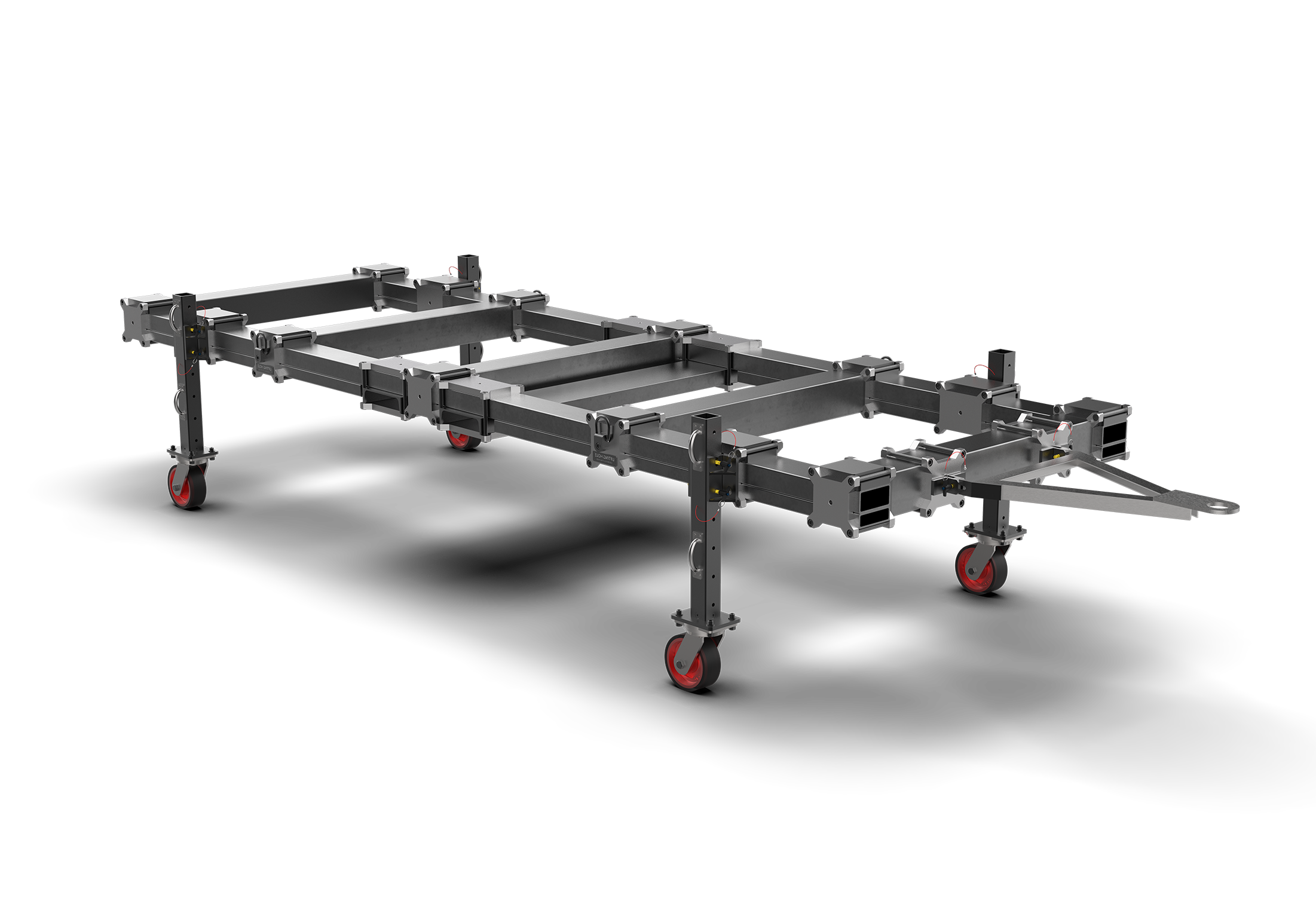

Work Platform

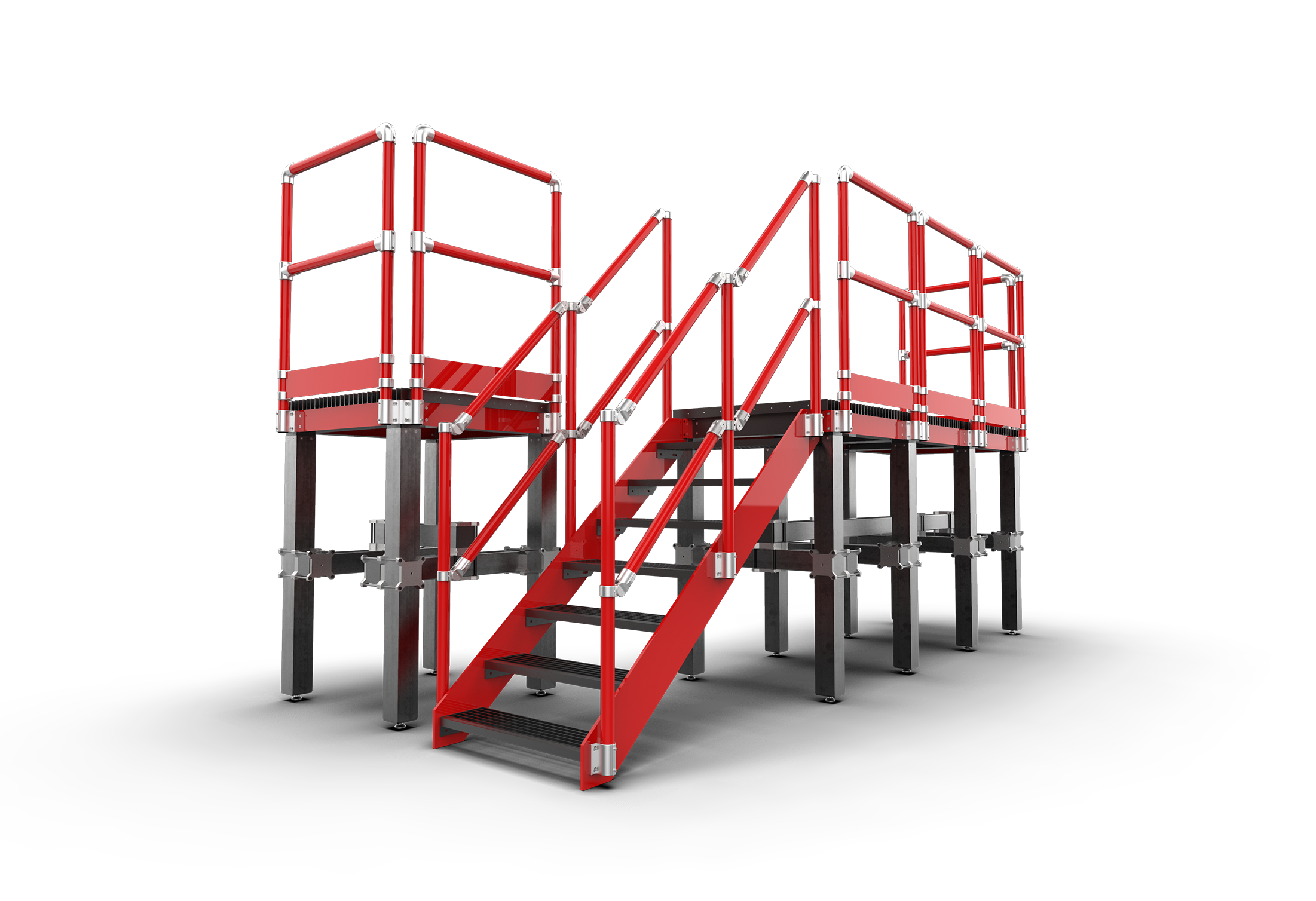

Complex Work Platform

GSE Engine Cart

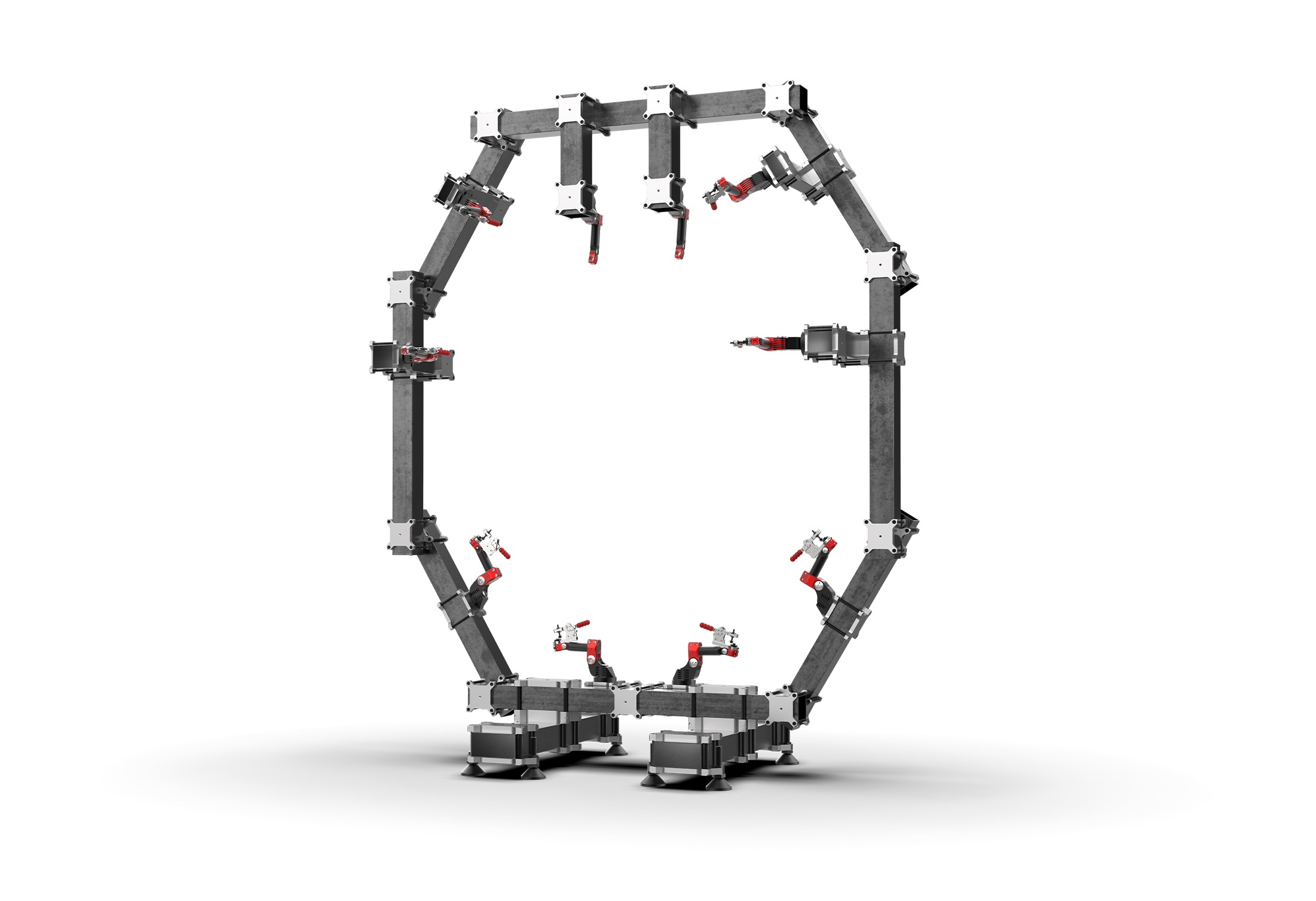

Hexagon Assembly Jig

Duct Cage

Complex Mechanical Assembly Cart

Want to Learn More?

To request the Harcourt® TDS document with more information on BoxJoint™, enter your information below and our team will be in touch with you shortly! Don’t forget to check your spam folder.

"*" indicates required fields